Sun Odyssey 47 – Rudder Fabrication

Deprecated: Function wp_make_content_images_responsive is deprecated since version 5.5.0! Use wp_filter_content_tags() instead. in /home/sites/jwsmarineservices.co.uk/public_html/wp-includes/functions.php on line 5414

Carried out during Winter 2013, The boat was not in the UK so we fabricated the rudder here at Southsea then sent it over to the Med for fitting.

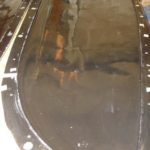

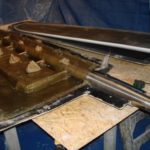

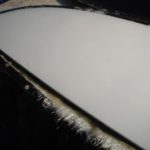

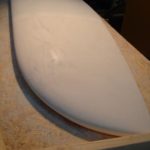

The pictures below show the following –

- Preparation of mould

- Gel coat layer before lay up

- Layer of chop strand matting

- Wet lay up of biaxial cloth

- Laying matting on mould

- Same as previous

- Wet lay up of chop strand

- Grinding mould ready for stainless work

- Fitting of stainless work – we lay stainless work onto one half of the rudder, apply 2 layers of chop strand matt over the top to bond in place using Crestomer 1152

- Apply wet bonding for joining the rudder

- Place top section of rudder on

- Joining both half together

- Clamp mould down for curing

- Curing finished, excess glass being trimmed

- Rudder sanded and ready for packing

Deprecated: Function wp_make_content_images_responsive is deprecated since version 5.5.0! Use wp_filter_content_tags() instead. in /home/sites/jwsmarineservices.co.uk/public_html/wp-includes/functions.php on line 5414

Deprecated: Function wp_make_content_images_responsive is deprecated since version 5.5.0! Use wp_filter_content_tags() instead. in /home/sites/jwsmarineservices.co.uk/public_html/wp-includes/functions.php on line 5414

Lay up process is as follows:

- 1 layer of 300 chop strand matting

- 1 layer of 300 biaxial cloth

- 1 layer of 600 chop strand matting

- 1 layer of 300 biaxial cloth

- 2 layers of 600 chop strand matting

- 1 layer of 300 biaxial cloth

- AME 6000 Vinyl ester based infusion resin was used in this application

- Ashlands White gel coat was used in this application.

Final Destination

The following pictures are of the rudder arriving at her final destination of Lanzarote and the fitting of the rudder to the boat.

Deprecated: Function wp_make_content_images_responsive is deprecated since version 5.5.0! Use wp_filter_content_tags() instead. in /home/sites/jwsmarineservices.co.uk/public_html/wp-includes/functions.php on line 5414