Osmosis Treatment & Copper Coat application on a C34 Sweden yacht

Came to JWS in 2019, Following some moisture readings it was found to have Osmosis and was in need of a full treatment. treatment,

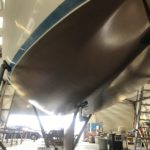

The owner accepted and we prepped her for the first job was to Gel peel the hull using a peeler.

We then blasted hull to open up the hull fibers and freeing the contaminates from the matting, this aids in the drying process.

At this point we removed all below the water line through hulls, unfortunately in this project none of the ball valves were serviceable so we supplied all new parts for 5 through hulls.

The new thru hulls were fitted and the ares cleaned.

We also removed the rudder, to access behind and cleaned ready for the same application as the hull.

After blasting she is hot washed 10 times over 14 days to aid in the drying process.

Once dry she was moved into the workshop ready for the hot-vac treatment.

In most Osmosis treatments only 1 course of hotvac is required, however due to the high level of moisture being retained in the hull, an additional 3 courses of hot vac were needed.

After hot vac treatment the whole hull was sanded and then 1 coat of Jotuns Epoxy megacote is applied.

The hull is filled and faired, then the following 5 coats of Megacote is applied.

Due to the severity of the osmosis and the amount of materials removed during peeling etc we applied an additional layer of 292 tapered cloth, this was applied using Ampreg 30 resin and peel ply cloth before the Epoxy Megacote was applied.

After the additional layer was applied and the Osmosis prevention epoxy applied and cured.

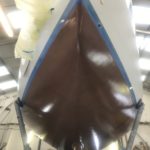

The boat is lifted so that the hull patches (Left from cradle) are sanded.

Finally the keel was coated with 5 coats of Epoxy.

It was time for some anti-foul, the owner opted for a Copper Coat application, please see this application below.