Osmosis Treatment on a Westerly Discuss 33

This boat came to us in 2018 for Osmosis Treatment followed by hull reinforcement

While with us she also had her thru hulls replaced and her rudder split, cleaned and re-bonded.

Normal procedure to start with a hull peel, however due to the high moisture levels a 2nd peel was required.

This was followed by a hull blast.

The hull was hot washed 10 time then she was moved into the shed for tenting up.

Next was the hot vac hull cure treatment, generally only 1 course is required but with this Discuss her moisture content was so high she needed 4 courses.

As she has a second peel and quite a lot of mat had to be removed to aid drying, we applied additional hull reinforcement on both the Port and Starboard side.

14 patches were agreed by the surveyor for reinforcement and comprised of 1 layer of 450 csm powder and the 2 layers of 600 csm bound matting with a tapered area of 25mm on all layers and between the keels will be 4 layers of 450 csm.

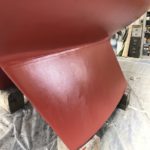

The hull was given a sand in preparation for the Epoxy bonding coat.

The hull was filled and fared before applying the further 4 Epoxy Osmosis coatings.

We finished the application with conventional Primer and Anti-foul.

During the Osmosis treatment both keels were blasted and 5 coats of Corro-tech epoxy were applied and new keel seams were done.

We also serviced and replaced the thru hulls on board

While in the shed receiving her osmosis treatment we also carried out some work to her rudder, before we could start the steering gear had to be removed.

With the yards assistance we lifted the boat to remove the rudder, upon removal of the rudder all bearing and seals were checked, this discuss needed a new upper and lower bearing set and a new lip seal, all of which we supplied and fitted.

All the old coating was sanded form the rudder and taken back to good glass, all blisters were removed form the laminate by grinding, and ground holes were filled with 830 epoxy filler and sanded fair.

The rudder was split in half and all foam from inside removed this allowed us to check the tangs and bonding.

The inside was grinded and prepped for the re-joining of the rudder sides.

Both sides were bonded together using a hi-strength gravicol bonding paste which was allows to cure and then this was laminated with 3 layers of 280 woven cloth and epoxy resin.

It was then filled and fared with 830 epoxy filler and sanded fare.

The rudder was then epoxied to the same spec as the hull, primed and antifouled.